- Home

-

Product

Advanced Po.. Powdered Ma.. Powdered Pr.. Advanced He..

- Solution

Powder addi.. High pressu.. Solutions o..- R & D

Test and sh.. Rotating Di.. Industrial .. Plasma Atom.. Gas atomiza.. Co-develope..- News

- About skyli..

Combined water and gas atomization equipment

Technical principle: Combining the characteristics and advantages of gas atomization technology and water atomization technology, the molten metal is dispersed through the first gas atomization, and then it is atomized by the water again in a very short time, which can produce superfine and spherical powder materials...

Immediately consultProduct introduction

Water and gas combined equipment

Water and air combined atomizing and pulverizing(granulation)device is a device designed to meet the production of water and air combined atomizing and pulverizing technology under atmospheric conditions,and is an industrialized mass production device.

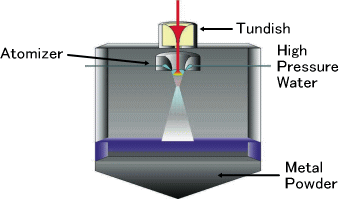

Working principle of high-pressure water-air combined atomizing powder(granulation)device

It refers to smelting metal or metal alloy under atmospheric conditions.Under the condition of gas protection,the metal liquid is atomized and broken into a large number of fine particles through the nozzle first and then water during the flow through the thermal insulation tundish and the diversion tube.Metal droplets,small droplets form sub-spherical or irregular particles under the combined effect of surface tension and rapid cooling of water during flight to achieve the purpose of milling.

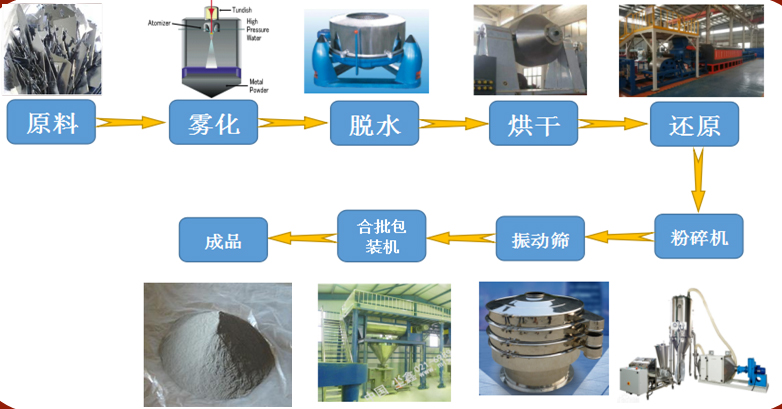

Schematic diagram of the process of producing metal powder by high pressure water and gas combined atomization:

Features

The equipment adopts non-magnetic stainless steel structure,with high strength and long life;

Oven pouring port has no forward-backward movement and high-precision spot casting;

Fast melting and heating,high production efficiency and good particle size distribution;

Hydraulic tilting furnace,stepless speed regulation,stable and safe;

Digital display and monitoring of atomized water height,stable control of atomization process parameters;

The full set of equipment adopts distributed control system,video monitoring of key parts,and friendly man-machine operation interface;

The powder particle size,shape and particle size distribution can be obtained by changing the atomization process and adjusting the process parameters,and it is related to the following parameters.

A. Alloy properties(viscosity of molten metal,surface tension);

B. Water and air atomization pressure;

C. Alloy atomization flow rate(determined by the diameter of the nozzle orifice);

D. Aatomizer nozzle geometry.

Introduction to production process

Raw materials-smelting-atomization-flouring-centrifugal dehydration(water content:5-15%)-drying-reduction-crushing-screening-combined batch-finished product packaging

Type: Powder Production Equipment

Input Size: blocks, plates, bars, rods, etc. raw materials in various sizes.

Processed Materials: metals or alloys

Applications: Principle:The ultra-high pressure water atomization equipment is designed to meet the production of the water atomization process under atmospheric conditions, and is an industrial mass production device. The principle is that the metal or metal alloy is,

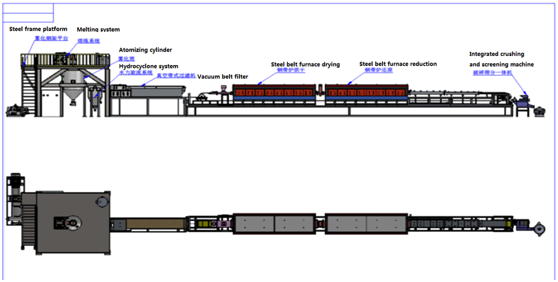

Schematic diagram of the overall layout(this figure is for reference only,and is not an acceptance standard)

European customer case

Cases of exporting to Japan

Field photos of metal powder produced by high-pressure water-gas atomization

Domestic Japanese-owned enterprise customer case scene

US Apple Mobile Phone Supplier Customer Case Study

Customer Site Cases in Taiwan

亚洲精品国产美女久久久| 东方av在线最新网址| 亚洲国内精品视频在线观看| 国产精品免费一区二区三区| 亚洲综合涩| 日本国产精品| 久久久久久久精品国产亚洲87| 免费A∨一区二区三区AV| 亚洲综合一区国产精品| 老司机午夜无码福利在线视频观看 | 能免费看片| 久久精品国产精品亚洲色婷婷| 欧美久久超级碰碰碰二区三区| 国产精品大片在线| 在线精品亚洲欧洲第一页| 亚洲爽视频一区| 国产亚洲在线久久精品视频| 日韩在线看片| 国产精品无码久久久久久电影| 久久香蕉国产| 秋霞电影网成人免费看片| 久久国产成人亚洲精品| 国产自在自线午夜精品视频| 久久人与动人物A级毛片| 国产在线a不卡免费视频| 成人在线免费看片| 国产99久久久国产精品免费观看| 国产欧美亚洲专区| 亚洲国产精品一区二区久久| 午夜免费看片| 亚洲国产成人久久| 亚洲欧美日韩综合在线一区二区三区| 久久伊伊香蕉综合精品| 亚洲精品免费在线观看视频| 国产精品二区| 亚洲视频一区二区不卡播放| 亚洲欧美中文在线一区视频大全| 夜色在线影院在线看片| 视频一区精品自拍亚洲ts清晰版| 88国产精品欧美一区二区三区| 亚洲精品高清国产麻豆专区| 久久中文精品视频| 波多野结衣色av一本一道| 久久精品国产中国久久| 色综合日韩| 九九免费精品视频| 国产精品手机在线观看| 精品国产成a人在线观看| 福利一区二区在线| 亚洲国产网址| 日韩精品一区二区三区中文字幕 | 国产福利视频精品视频| 国产美女无遮挡免费观看| 亚洲天堂久| 亚洲午夜高清| 狠狠色丁香九九婷婷综合五月 | 亚洲欧美日韩中另类在线| 久久香蕉国产线看观看精品| 蜜桃视频一区二区三区四区| 在线看片成人| 亚洲综合精品一二三区在线| 国产精品成人影院| 亚洲最新|国产视频一区| 久久丫精品国产亚洲电影| 囯产精品一品二区三区| 在线观看亚洲精品福利片| 亚洲国产精品线路久久小说| 成人国产精品一区二区免费看| 国产毛片免费| 亚洲一区二区国产精品无码| 免费看h片| 亚洲图欧美日韩一区视频在线观看 | 伊人色色网| 国产成人啪精品午夜在线观看| **影院亚洲一区高清完整视频 | 精品亚洲成a人在线观看| 欧美专区日韩专区| 久久国产精品网| 一区二区三区高清| 国产亚洲精品自在久久app| 国产国拍精品视频免费看| 日韩午夜片| 久久综合国产亚洲精品首页| 免费网上看片| 亚洲精品你懂的在线观看| 久久国产精品系列| 99re在线这里只有精品免费| **亚洲精品视频18苍井空| 亚洲欧洲国产精品久久| 最新国产精品久久精品| 在线天天看片视频免费观看看| 有没有免费看片网址| 在线看片**免费app| **片在线看| 久久丝袜精品中文字幕| 国产亚洲欧美一区二区三区| 国产精品精品| 91看片在线看| 热99精品| 精品亚洲无人区一区二区| 伊人一区| 国产小视频在线免费观看| 国产精品高清视频免费| 伊人久久大香线蕉无码麻豆| 九九精品免费| 免费播放18xxxx国产| 国产极品精品免费视频| 亚洲精品国产精品| 日韩福利一区| 精品国产免费第一区久久| 亚洲另类自拍视频一区| 国产精品久久久久鬼色| 国产精品**在线观看| 一区二区三区视频播放亚洲狠狠 | 国产精品公开免费视频| 四虎影视国产精品亚洲精品| 黄色一级片免费看| 欧美日韩视频一区二区三区| 8x8x精品国产自在现线拍| 627亚洲福利视频一区二区| 国产精选亚洲视频| 又大又硬又爽免费视频| 手机免费看片日韩| 久久久免费观看| 亚洲V欧美V日韩V国产V| 看片免费的| 91精品福利一区二区| 精品国产精品久久一区免费式| 中文字幕亚洲欧美| 国产原创在线视频| 亚洲国产精品久久一线| 国产精品99久久久久久人| 亚洲专区日韩精品| 久久久久无码精品国产AV性色| 久久久久久一区二区三区| 久久这里有精品国产免费| 亚洲 欧美 日韩 视频一区| 久久视精品| 婷婷国产成人久久精品激情| 国产**免费看| 国产69精品久久久久9999| 中文字幕无码久久精品专区| 午夜看片在线观看视频免费| 高清无码久久久久久| 亚洲欧美精品动漫| 久久91综合国产91久久精品| 亚洲国产成人久久精品不卡 | 在线看片三级| 区国产精品搜索视频| 成人国产精品一区二区免费看| 亚洲欧美国产精品一区| 好紧我太爽了视频免费国产| 91久久99| 国产精品v日韩精品v欧美精品| 国产精品亚洲影院| 亚洲一区二区三区在线视频| 久久精品国产99久久六动漫| 国产一区二区三区久久| 久久 精品 国产| 欧美国产日韩精品| 亚洲日韩视频写真一区| 啪啪人妻| 国产在亚洲| 国产第一草草影院| 亚洲一二区视频| 亚洲**视频一区| 香蕉99国内自产自拍视频| 国产青榴视频在线观看网站| 免费看片影院| 欧美午夜视频一区二区| 国产亚洲色视频在线| 99精品欧美一区二区三区美图 | 性爱一区| 国产曰又深又爽免费视频| 欧美激情亚洲一区中文字幕| 亚洲依依成人综合网站| 国产精品久久一区二区三区夜色| 日韩人妻无码中文字幕第一页| 精品无码久久久久久国产| 色婷婷久久合月综| 国产精品久久久久a影院| 大伊香蕉精品视频一区| 亚洲涩涩精品专区| 欧美亚洲高清视频一区| 久久精品国产亚洲AV成人片| 中文字幕久久综合久久88| 久久国产精品99久久久久久老狼 | 国产精品久久久亚洲**| 亚洲精品无码久久久久久电影网 | 精子网久久国产精品| 看片在线观看视频免费| 久久国产精品免费视频| 亚洲国产成人无码av在线播放| 081亚洲福利视频一区二区| 8090成人午夜精品无码| **做片就在线看| 高清免费毛片| 国产永久在线| 亚洲精品免费在线视频观看| 亚洲AV高清在线观看一区二区三区 | 国产**在线| 国产精品久久综合亚洲 | 黄色网站入口在线观看| 青青在线精品视频| 国产主播精品系列| 国产簧片免费在线播放| 国产精品亚洲综合网站| 国产精品爽爽va在线观看无码| 强奷白丝美女在线观看| 国产精品亚洲一区二区无码| 日韩在线国产| 亚洲欧美高清国产精品| 揄拍成人国产精品视频| 亚洲国产精品无码久久悠| 日韩精品一区二区三区视频| 国产精品娱乐| 亚洲精品清国产一线久久| 久久亚洲国产| 亚洲视频一区二区在线观看| 亚洲欧美国产精品一区| 欧美在线观看www| 伊人五月在线| 狠狠综合久久综合88亚洲日本 | 午夜片免费看| 福利视频 亚洲一区| 国产精品无码久久久久久蜜臀AV| 亚洲国产人久久久成人精品网站| 亚洲欧美国产毛片在线| 中文字幕亚洲视频一区tv破解版| 国产免费不卡在线| 久久亚洲女同第一区| 日韩欧美一区二区三区久久| 亚洲视频一区tv破解版| 手机在线观看免费国产视频网址你懂得| 亚洲欧美日韩中文综合在线不卡| 国产成人亚综合91精品首页| 亚洲国产欧美在线人成| 免费看片子的app有哪些| 国产精品天干天干| 亚洲中文无码一区二区三区| 久久综合九色综合97婷婷| 亚洲国产高清在线观看视频| 369欧美亚洲视频一区| 免费一级淫片| 中文国产成人精品久久一| 国产又粗又猛又爽的视频| 视频一区二区在线| 久久久久精品99九九国产| 久久久午夜视频| 成人在线看片| 手机看片1204基地免费| 国产亚洲精品精品国产亚洲综合 | 动漫亚洲欧洲视频一区| 国产精品手机视频在线观看| 亚洲新视频一区二区三区四区五区| 欧美国产精品| 国产国模精品嫩模大尺度| 成人精品视频网站| 99精品一区二区| 国产96在线| 国产欧美亚洲精品第一页亚洲欧美| 久久999国产精品美女高潮| 国内精品久久国产大陆 | 日韩一区二区三| 免费看的福利片| 亚洲阿v天堂**一区下载| 久久国产亚洲精品超碰热高清| 五月婷婷久久综合| 中文字幕在线观看不卡| 日韩无码二区| 99视频在线免费观看| 久久免费国产视频| 免费a在线观看播放| 看免费黄色一级片| 免费看色片| 在线观看看片免费| 国产精品wwwcom976con| 可以免费看片子的软件| 亚洲国产欧美精品一区| 国产精品一二三区在线观看公司 | 片在线看| 小泽玛利亚在线看片| 亚洲国产视频在线一区| 手机免费看片网站| 在线看片01| 亚洲视频一区二区三区频道| 201亚洲福利视频一区二区| 国产亚洲欧美精品在线播放 | 精品国产污污免费网站| 99国产精品2018视频全部| 精品国产自在现偷| 在哪里可以在线看片| 亚洲欧美另类视频一区| 亚洲国产亚洲ww92922| 亚洲愉拍自拍视频一区正在播放| 国产亚洲精品中文字幕| 国产精品自拍在线免费观看| 青青精品视频国产| 亚洲视频一区欧美视频播放| 亚洲欧美中文日韩一区视频 | 精品多毛少妇人妻av免费久久| 国产精品99久久免费观看| 国产精品影片| 日韩亚洲欧美视频一区| 成年男人看的免费的片| 日本理论片免费看高清| 免费**就在线看| 手机看片基地免费1024| 国产精品视频一区二区三区w| 三机片免费看| 亚洲国产精品久久久久| 国产成人精品久久| 色婷婷精品| 91在线真实产子伦| 视频一区**字幕高清在线| 亚洲精品**国产| 072亚洲福利视频一区二区| 亚洲**视频一区| 三极片网站免费看| 久久国产综合精品欧美| 72种姿势欧美久久久大黄蕉| 免费国产黄在线观看| 久久这里只精品国产免费99| 亚洲国产精品一区二区第一页| 国产精品自拍电影在线观看| 香蕉视频免费看片| 欧美大色| 国产亚洲欧美在线中文bt天堂| 久久人妻xunleige无码| 久久精品国产精品亚洲tv破解版| 久久无码中文字幕精品久久| 日韩午夜精品视频一区二区三| 亚洲国产成人91成人版| 伊人久久免费| 国产精品自在线| 亚洲精品 日韩精品| 国产精品视频一区无码| 99ri在线精品视频在线播放| 国产欧美日韩精品专区| 欧美99久久精品乱码影视| 国产精品99久久久久久98AV| 一道本亚洲视频一区二区三区| **爱片在线免费看| 一区二区中文字幕| 无码亚洲视频一区二区3d| 在线看片免费观看不卡| 亚洲日比视频| 精品国产三级av在线| 免费视频在线观看69| 亚洲一区二区精品视频在线观看| 久久一区二区三区免费| 国产无码swag专区| 亚洲日韩视频播放一区| 亚洲欧美日韩国产精品| 国产亚洲精品久久久久久无| 亚洲最大视频一区| 欧美日比视频| 亚洲专区视频一区| 久久国产毛片| 国产精品av| 国产在线免费看片| 欧美精品v国产精品v| 丰满爆乳一区二区三区| 3344成年人在线看片福利| 九九精品久久久久久久久| 9丨精品人妻一区二区三区蜜桃| 狼友av永久网站免费极品在线| 国产精品欧美亚洲日本高清| 99热这里只有精品5| 精品国产亚洲一区二区三区大结局| 亚洲国产成人久久精品app| 天天看片高清视频免费| 扒开粉嫩的小缝隙喷白浆视频| 久久久久久久精品国产亚洲87| 视频一区亚洲高清| 丁香婷婷综合网| 久久国产亚洲欧美日韩精品| 谁有免费看片的网站| 天天色天天操综合网| 国产成人无码综合亚洲日韩| 手机看片国产免费| 亚洲中文字幕国产av| 国产手机免费精品视频| 伊人精品在线观看| 国产曰批免费视频播放免费| 亚洲高清在线观看| 国产精品**在线| 亚洲欧美视频一区二区三区| 午夜福利视频偷拍精品免费| 亚洲综合无码一区二区痴汉| 国产精品亚洲二区在线观看| 视频一区亚洲视频无码2| 国产精品成人69xxx免费视频| 久久久91精品国产一区二区三区| 国产三级在线免费看片| 久久精品国产成人Av| 精品国产91| 亚洲国产亚洲区| 99热在线精品观看| 亚洲黑人视频一区| 日韩中文在线视频| 1024国产成人精品视频| 国产a区午夜免费视频| 免费看的黄色片子| 一区二区视频在线观看| 国产精品亚洲欧美一区在线| 亚洲一区二区情侣| 一本无道码日韩精品一区在线观看 | 736亚洲福利视频一区二区 | 久久视频在线国产亚洲精品| 伊人色综合久久天天伊| 国产精品亚洲专区无码不卡| 国产亚洲综合在线| 国语淫片免费看| 精品人妻无码专区中文字幕| 午夜看片免费| 久久香蕉国产线看观看精品| 丰满熟妇乱又伦在线无码视频| 亚洲综合一区二区精品导航| 国产不卡视频在线观看| 免费看v片在线观看| 久久精品人人爽| 最新国产精品福利在线播放| 国产不卡免费视频| 国产亚洲人成a在线v网站| 久久亚洲AV成人无码| 片库网免费看电影| 91久久夜色精品国产网站| 久久精品色| 免费观看国产一级视频| 日韩免费一区二区| 看片网站免费观看| 久久女人天堂| 91欧美国产| 免费的看片软件| 国产线路中文字幕| 香蕉久久一区二区三区| 欧美日韩亚洲国产一区| 国产午夜人做人免费视频观看| 欧美日韩在线看片| 国产美女黄频大全免费观看| a在线观看免费| 国产精品永久免费视频| 69国产视频| 手机在线看片片| 久久国产亚洲精品精品久久国产| 贵州少妇一级毛片| 精品国产高清自在线一区二区三区 | 久久精品视频国产亚洲| 国产午夜视频在线| 久久这里有精品国产| 日韩黄色中文字幕| 综合无码综合网站| 亚洲视频在线视频一区| 国产女人aaa级久久久级| 99这里精品| 精品国产三级av在线| 视频一区在线播放| 日韩在线一区二区| 看免费**儿| 亚洲免费国产视频| 真实国产乱人伦在线视频播放 | 欧美亚洲日本精品| 国产精品igao视频网免费播放| 久久精品国产一| 久久精品国产亚洲vv麻豆| 亚洲精品中文字幕乱码影院| 国产三级精品三级在专区| 久久精品国产**高清yw| 久久久久久国产精品网站| 国产永久免费视频| 亚洲福利国产精品合集在线看| 91普通话国产对白在线| 久久久久久精品人妻免费网站| 无限免费看片的视频下载| 欧美日韩亚洲国内综合网| 国产精品国产三级国产专区不| 亚洲国产精品欧美| 99精品国产在热2019| 精品乱人伦| 玖玖香蕉视频| 看片在线观看视频免费| 亚洲精选国产视频| 手机看片日韩免费观看| 国产精品久久一区二区三区夜色| 丰满爆乳一区二区三区| 日本影院一区| 四虎影院久久久| 免费看日韩一级片| www.亚洲国产| 五月婷婷中文| 国产免费精品久久| 国产女王免费踩踏调教视频| 国产精品**在线播放| 精品视频手机在线观看免费| 日韩无码视频一区| 性爱一区| 中文字幕三级久久久久久| 成人免费看片网站| 看国产精品视频| 亚洲国产精品无码久久一| 人妻少妇精品久久| 国产一区二区精品视频| 免费看av片| 亚洲精品ady狠狠戳| 午夜在线一区| 日韩AⅤ无码中文无码电影| 精品一久久香蕉国产线看观看下| 国产亚洲欧美精品视频| 欧美亚洲国产日韩综合在线| 一级爽片免费看| **精品影院| 亚洲欧美丝袜精品久久| 国产精品一区二区三区| 能免费看片| 精品亚洲欧洲| 五月激情综合| 四虎在线视频免费观看| 国产精品最新| 欧美激情第一区| 亚洲色综合视频一区正在播放| 免费国产激情视频| 免费国产自拍视频在线观看| 国产精品| 美里有纱迅雷亚洲视频一区| 亚洲视频一区欧洲| 色一把在线看片| 黄污片在线看| 亚洲国产欧美日本在线| 亚洲mv国产mv在线观看| 亚洲永久精品唐人导航网址| 成人久久精品| 久久这里精品国产99丫e6| 不卡在线看片| 精品久久一区二区| 久久99爰这里有精品国产| 中文字幕在线观看一区| 久久精品国产72精品亚洲| 久久精品久噜噜噜久久| 免费a级毛片| 在线亚洲自拍| 久久精品国产亚洲四虎| 国产欧美精品一区二区三区| 视频一区亚洲视频抖音| 久久亚洲春色中文字幕久久久| 国产精品99久久久久久宅男| 亚洲国产精品中文字幕| 在线看片的网站| 91看片在线看| 无码精品一区二区久久久 | 1024在线观看国产精品| 国产va免费精品高清在线| 亚洲欧美日韩国产精品专区网| 亚洲国产精品亚洲人成| 国产亚洲视频一区中文字幕| 1024看片免费| 欧美一级免费电影| 原创久久精品国产**麻豆| 最新亚洲国产有精品| 久久精品国产精品亚洲色婷婷麻 | 亚洲AV自慰白浆喷水网站少妇 | 香蜜沉沉烬如霜免费观看国产剧| 国产在线精品美女观看| 国产精品亚洲影院| 亚洲国产男同志gay在线| 手机在线看片影院| 亚洲精品视频在线| 国产午夜亚洲精品久久| 国产精品你懂的在线播放| 精品久久国产| 伊人网成人| 亚洲欧美精品一区二区| 91久久久久无码精品国产软件| 在线观看国产精品第一区免费| 日韩手机专区| 日韩欧国产精品一区综合无码| 美女洗澡av片免费看| 理伦片在线看| 国产精品电影久久久久电影网 | AV无码一区二区三区国产| 久久精品蜜芽亚洲国产| 国产美女精品美女免费视频| 亚洲国产视频网| 久久香蕉精品国产亚洲AV最新| 国产精品不卡在线| 亚洲AV成人无码久久精品换脸| 无码免费人妻超级碰碰碰碰| 视频区美女主播国产精品| 亚洲不卡视频一区二区在线观看| 亚洲一区www| 91久久夜色精品国产九色| 国产精品久久亚洲不卡999| 国产成人综合久久精品免费| 有没有可以看片免费的直播| 啪啪天堂网| 国产欧美亚洲精品专区| 一区福利视频| 99久女女精品视频在线观看| 804亚洲福利视频一区二区 | 精品成人免费国产片| 亚洲AV综合色区手机无码一区| 91精品国久久久久久无码蜜桃| 最新国产亚洲免费在线视频| 久久国产精品真实| 国产精品久久久久久AV福利| 国产又黄又爽又猛免费视频播放 | 手机看片福利永久免费国产| 国产精品成人69xxx免费视频| 国产爽妇精品| 国产高清精品久久| 久久semm亚洲国产| 106亚洲福利视频一区二区| 三极片在线免费看| 国产国模一区二区三区四区| 亚洲视频免费一区高清| 最新国产一区二区精品久久| 国产大片免费观看| 国产精品亚洲免费视频| 97精品人妻无码专区在线视频| 青青青国产免费观看| 国产亚洲欧美精品在线观看| 亚洲av午夜福利精品一区人妖| 国产AV网站18禁止人| 亚洲激情视频免费一区 | 国产在线播放网址| 看片网站在线免费| 成人午夜视频在线播放| 手机怎样免费看片| 久久99热成人精品国产| 有什么免费看片软件| 亚洲精品在线影院| jizzjizz国产免费**| 亚洲综合另类| 新26uuu在线亚洲欧美| 亚洲女人国产香蕉久久精品| 亚洲午夜国产精品无码中文字| 伊人久久婷婷| 日韩 欧美 亚洲 视频一区| 伊人网综合在线视频| 精品伊人久久久香线蕉| 免费可以看污片的软件下载| 国产福利免费观看| 久热精品免费视频| 国产视频一区免费观看| 精品免费久久| 国产福利免费视频| 亚洲欧美国产免费| 精品+无码 免费 国产| 精品国产v无码大片在线看| 亚洲天堂第一区| 亚洲精品国产第一久久| 亚洲国产最新视频在线观看| 丰满爆乳一区二区三区| 亚洲国产最新视频在线观看| 亚洲国产成人久久精品app| 免费看片app软件大全| 国产黑丝视频在线观看| 免费手机看片你懂得| 亚洲欧美视频一区二区三区| 亚洲欧洲视频一区百度| 72种姿势欧美久久久大黄蕉| 亚洲欧美日韩在线国产| 国产亚洲精品美女2020@久久 | 亚洲大胆精品337p色| 欧美日韩国产免费一区| 麻豆91av| 国产欧美精品一区二区三区| 午夜少妇精品视频小电影| 亚洲愉拍一区高清完整视频下载| 精品国产第一页| 久久国产欧美日韩精品| 在线观看亚洲成人| 看片app免费下载| 久久久久久精品免费免费英国| 视频一区视亚洲日韩| 在线欧美国产| 国产精品无码久久久久| 亚洲一区黄色| 国产a v无码专区亚洲av| 国产亚洲精品精品国产亚洲综合| 欧美在线Aⅴ性色| 在线观看片免费视频无码| 亚洲天堂网在线视频| 国产在线视精品在亚洲| 国产亚洲精品美女久久久久久久久| 手机看片1024在线免费观看| 国产精品xxx| 中文字幕在线精品视频站app| 伊人国产精品| 久热这里只有精品6| 免费看片app在线观看| 国产一片免费观看| 亚洲综合色秘密影院秘密影院| 久久这里只精品国产免费99| 久久精品国产亚洲桃乃木香奈| 亚洲国产成人精品一区91| 国产精品自拍一区| 国产日黄色网站| 在线看片免费**久试看| 国产精品手机视频免费观看| 激情婷婷网| 亚洲国产日韩欧美视频一区| 四虎影视国产精品一区| 国产精品亚洲欧美大片在线| 国产免费网站看v片元遮挡| 三极片免费看| 国产娱乐精品| 亚洲AV成人无码精品久久不卡| 色婷婷综合在线| 609亚洲福利视频一区二区 | 国产精品亚洲精品日韩已方| 精品国产电影久久久久| 亚洲一区小说区中文字幕| **精品一区| 无码精品一区二区三区免费16| 国产成人精品免费青青草原app| 国产两男一女3p免费视频| vr专区精品中文字幕| 99在线观看国产精品| 人妻精品久久久久中文字幕一冢本| 国产在线观看91| 日韩亚洲视频一区二区三区四区| 亚洲国产精品导航| 国产免费一片| 亚汌国产一区二区三区| 日韩一级影院| 99精品久久| 在线看片1788| 九一色视频| 视频一区亚洲制服tv破解版| 亚洲美女精品xx| 99久久香蕉国产线看观香| 99JK无码免费| 三级免费看片| **字幕视频一区二区三区 | 无码aⅴ免费中文字幕久久| 2346亚洲福利视频一区二区| 新sss亚洲视频一区| 久久精品国产精品亚洲无广告弹窗| 国产成人户外露出视频在线| 狠狠综合欧美综合欧美色| 香蕉精品国产高清自在自线| 国产精品久久国产精品久久| 国产一级一极性活片免费观看| 国产精品福利久久2020| 成人在线一区二区三区| 国产成人精品在线观看| 成年站免费网站看v片在线| 久久精品 国产精品| 精品国产不卡一区二区三区| 国产亚洲欧美精品视频| 国产精品99r8免费视频| 亚洲综合视频免费一区| 国产亚洲一区二区三区不卡| jlzz在线看片| 国产欧美日韩在线播放| 日本亚洲一区二区视频| 国产一区二区精品视频| 久久精品免视看国产| 亚洲国产成人精品女人久久久| 日韩人妻无码一区二区三区久久九九| 国产欧美一区二区三区久久| 日韩AV免费大片| 伊人久久综合网亚洲| 伊人天伊人天天网综合视频| 亚洲男人天堂网址 | 亚洲AV日韩AV永久无码网站| 免费A级毛片无码A∨中文字幕| 三级毛片基地| 亚洲精品视频二区| 三级精品在线观看| 亚洲精品在线观看免费视频网站| 青草国产在线视频免费| 亚洲精品在线观看免费视频| 日韩亚洲欧美精品视频| 国产精品久久xx| 国产黄色免费网站| 国产精品久久久久精品一级| 久久夜色精品国产| 亚洲国产视频一区在线观看| 精品国产女人爽到喷水| 久久久久久精品国产女| 久久精品99国产精品亚洲| 久久se精品一区二区国产| 97精品国产手机| 国产精品亚洲w码日韩中文| 69国产成人综合久久精品91| 911国产精品| 99热这里只有成人精品国产| 好吊妞欧美视频免费| 午夜福利在线观看成人| 高清无码五月天| 精品国产乱码AAA一区二区| 一区二区日韩国产精品| 亚洲视免费播放一区视频在线观看| 视频一区亚洲欧美系列| 免费纪录片在哪里看| 中文字幕综合久久久久| 视频一区漫画图片亚洲| 欧美另类在线视频| 97超碰国产精品无码| 亚洲国产精品自产拍在线播放| 国内精品久久影视免费| 99久久久久国产| 国产福利网站在线观看红一片| 亚洲综合色在线播放www| 国产欧美一区二区精品性色| 在线播放国产不卡免费视频| 精品国产亚洲欧美| 免费亚洲一区视频| 亚洲国产欧美另类视频在线观看| 欧美精品亚洲精品日韩专区| 国产成人精品免费大全| 亚洲综合AV在线在线播放| 久久久久久精品国产下载| 国产一区二区三区免费观看在线| 国产拍偷精品网| 亚洲色综合视频一区正在播放| 国产精品福利视频在线播放| 国产精品无码无卡免费观| 色www亚洲| 亚洲精品欧洲久久婷婷99| 国产精品第五页| 国产三级网址| 国产黄在线观看免费观看不卡| 亚洲色综合视频一区tv破解版| 视频一区视频二区亚洲视频| 免费一级欧美横片在线看| 久99久热只有精品国产99| 99精品视频看国产啪视频| 欧美精品在线看| 日本欧美亚洲精品| 精品国产九九在线观看| 亚洲三区视频| 国产一级片免费在线播放| 国产精品日韩在线一区| 免费看**儿的app| 欧美一级免费电影| 人禽交 欧美 网站免费| 亚洲欧美日韩精品专区| 亚洲日本网站| 精品视频手机在线观看免费| 国产精品自拍在线免费观看| 蜜桃tv在线看片| 国产午夜无码福利在线看网站| 欧亚无码视频| 国产精品亚洲欧美在线播放| 免费的看片网址| 亚洲男人天堂网| 国产在线观看WWW鲁啊鲁免费| 国产美女精品自在线拍| 青青在线看片| 久久综合综合久久| 国产国拍亚洲精品av| 亚洲日韩视频一区二区在线观看 | 亚洲国产日韩在线观看| 亚洲综合色秘密影院秘密影院| 国产精品污| 成人在线免费看片| 国产精品一区二区三区久久| 亚洲精品色网| 欧美成人一级视频| 国产黄网站免费| 精品国产电影久久九九| 国产成人精品福利网站人 | 激情婷婷网| 啪啪人妻| 4455vw在线看片| 久久美女精品国产精品亚洲| 欧美日韩亚洲精品在线| 免费亚洲国产视频| 欧美精品亚洲精品日韩精品| 国产欧美亚洲精品a| 在线播放国产一区| 久久国产免费视频| 色噜噜的亚洲男人的天堂| 久久国产亚洲精品超碰热o| 免费看理论片中字国产| 精品国产成a人在线观看| 91精品国产一区自在线拍| 亚洲国产精品一区二区视频| 久久精品国产亚洲综合色| 亚洲国产精品线路久久6| 日片在线看| 国产91观看| 视频一区亚洲欧美激情| 欧美日韩精品在线观看| 国产精品久久网| 亚洲欧美日韩综合在线一区二区三区| 亚洲婷婷综合五月天| 两个人看的www免费视频中文| 久久综合资源| 手机免费线上看片| 国产福利在线观看免费第一福利| 国产香蕉久久| 国产精品欧美大片在线观看| 国产91在线播放| 久久久久精品国产**| 日韩欧美亚洲国产| 国产99视频精品黄瓜视频app| 国产一区中文字幕在线观看| 久久精品国产亚洲| 青青青国产精品国产精品美女| 亚洲另类欧美综合久久图片区| 麻豆国产亚洲欧美视频一区| 国产偷国产偷高清视频| 国产主播精品福利在线| 久久精品国产**麻豆车振| 成人爽片免费看| 日韩毛片基地| 中文字幕91在线| 亚洲AV无码一区二区一二区色戒| 国产伦码精品一区二区| 最新亚洲视频免费一区| 亚洲激情区| 欧日韩视频| 国产一区二区三区免费观看在线| 国产在线一二三区| 1024国产成人精品视频| 99v久久综合狠狠综合久久| 老黄看片免费版| 亚洲免费视频网址| a无码久久久久不卡网站| 久久精品国产亚洲公众号| 久久福利青草精品资源站免费| 国产精品久久久亚洲| 91在线一区二区| 精品国产呦系列在线观看免费| 久久国产精品免费网站| 久久久91精品国产一区二区三区| 精品九九视频| 久久亚洲热| 久久精品国产99久久久香蕉| 国产精品久久久久国产这里有精品| 久久免费网| 国产在线播放原创精品福利| 无码视频一区 二区 三区| 三极片在线看| xxx国产精品视频| 亚洲国产区男人本色VR| 国产欧美日韩专区| 无码亚洲视频一区二区tv破解版| 欧美视频一二三区| 韩国精品福利一区二区| 免费看的污片| xxx国产精品视频| 无码污污网站| 中文字幕一区在线播放| 成年女人永久免费看片| 国产福利91精品一区二区三区| 欧美日本综合一区二区三区| 哪个网址可以免费看片| 欧美精品亚洲在线| 国产精品日本亚洲欧美| 成人一级免费视频| 精品天海翼一区二区| 亚洲精品国产在线观看| 亚洲**中出视频一区迟到的秘书| 国产午夜亚洲精品久久| 久久精品国产69精品亚洲| 精品久久久久久国产91| 亚洲国产精品久久人人爱| 88国产精品欧美一区二区三区 | 亚洲欧美国产精品一区| 日本在线看片免费**| 国产在线高清亚洲精品一区| 日韩精品视频中文字幕无码| 久久综合资源| 国产成人精品视频一区二区不卡 | 午夜视频在线观看国产www| 亚洲va主播一区二区视频| 一级毛片不卡在线播放免费| 黄色国产视频| 在线日韩日本国产亚洲| 亚洲精品国产导航| 精品精品国产高清a级毛片| 久久国产精品专区| 波多野结衣中文字幕一区二区| 亚洲欧美日韩久久一区二区三区| 9420看片免费观看1| 在线观看精品国产福利片| 久久黄色高清视频。| 欧美综合久久| 99热这里只有精品国产66| 免费看片手机在线| 视频一区**字幕在线播放| 一本色道无码道在线观| 国产一区二区精品久久91| 亚洲国产精品区| 视频一区**字幕手机版下载| 国产亚洲福利精品视频| 免播放器在线免费看片| 亚洲一本视频一区中文在线播放| 亚洲国产美女精品久久久久| 国内精品国产三级**久| 久草免费在线观看国产视频| 精品成人久久| 久久噜噜久久久精品66| 久久九九精品国产AV片国产| 久久国产夫妻| 久热这里只有精品3| 亚洲日韩国产精品久久无码综合| 丰满熟妇乱又伦在线无码视频| 国产精品免费久久久久影院| 日韩精品中文字幕一区三区| 亚洲国产精品67194成人| 亚洲一区**在线观看| 国产精品视频一区无码| 国产精品自拍视频观看| 亚洲国产成人精品久久久| 国产精品久久久亚洲456| 2022在线国产一区| 免费国产不卡午夜福在线观看 | 国产成人亚洲毛片| 国产主播啪啪| 日韩第四页| 久久久久a v| 亚洲专区在线播放| 亚洲一区网站| 2021国产麻豆剧传媒免费直播| 国产精品亚洲专区在线观看 | 国产免费看久久久| 91福利一区二区三区| 亚洲免费一级视频| 亚洲综合色视频| 久久最新免费视频| 亚洲青青草原| 亚洲自偷自拍另类图片二区| 亚洲国产精品一区二区www| 一区二区三区无码av| 伊人久久青青| 在线亚洲欧美日韩精品| 亚洲精品欧美日韩在线观看| 手机看片免费福利盒子| 亚洲欧美国产成人在线视频| 国产亚洲精品视频在线观看| 国产午夜免费不卡精品理论片| 国产精品亚洲影院| 欧美一区二区在线观看| 午夜理论无码片在线观看免费| 国产伦子一区二区三区四区| 国产在线观看精品| 国产青青草视频| 亚洲日韩区在线电影| 成人一级黄色毛片| 国产高清精品| 亚洲视频免费一区百度网盘| **在线看片| 国产91页| 国产午夜三区视频在线| 亚洲国产精品一区二区久久hs| 欧美一区二区三区综合色视频| 91网址在线播放| 久久精品国产亚洲无删除| 亚洲国产中文在线免费视频| 国产精品视频video| 国产精品视频白浆免费视频| 国产亚洲欧美日韩在线视频| 欧美视频二区| 亚洲精品午夜在线| 免费手机看片1024| 久久91亚洲精品中文字幕| 亚洲一区二区三区不卡在线播放| 精品性久久| 国产乱人伦免费视频播放| 国产精品女同磨豆腐| 国产主播精品系列| 亚洲天堂免费观看| 亚洲色婷婷一区二区三区| 亚洲国产欧洲久久精品| 高清国产精品久久| 亚洲国产欧美中文| 伊人一区| 国产a视频在线免费观看| 久久精品国产精品亚洲| 手机看片1024国内免费| 久久人人做人人妻人人玩精| 久久国产精品亚洲色| 国产极品精品免费视频| 黄在线看片免费**无毒不卡| 国产精品第7页| 亚洲2022国产成人精品无码区| 国产精品激情免费视频| 亚洲精品国产亚洲第一| 久久久婷婷| 亚洲综合另类| 午夜国产精品福利视频100集| 91一区二区视频| 在线播放精品一区二区啪视频| 女人高潮特级毛片| 久久婷婷五月国产色综合| 91福利在线看| 国产精品无码一区二区桃花视频| 视频一区亚洲视频免费观看| 最新国产精品| 东京热久久综合久久88| 亚洲高清一区手机版高清完整视频| 手机看片免费福利盒盒子| 成人欧美一区二区三区| 国产精品**无人区一区| **免费看一级片| 欧美日韩成人在线视频| 色一乱一国产一二区免费视频 | 国产1区2区3区在线观看| 黄色网站视频三区| 免费网站看v片在线不卡| 亚洲黄色片在线观看| 亚洲成av人片在线观看| 国产精品视频6| 亚洲精品国产成人在线| 亚洲午夜片| 亚洲日本视频一区| 亚洲黄色自拍| 免费在线观看国产自拍| 欧洲亚洲国产综合图片| 无码按摩| 亚洲自拍视频一区| 国产精品久久久久久久福利院 | 国产女主播视频免费观看| 国产精品自拍电影在线| 伊人五月在线| 国产精品久久看| 欧美另类视频在线| 亚洲国产麻豆精品久久| 成人小视频在线观看免费| 粉嫩小泬图片国产20p| 欧美日韩国产亚洲视频一区| 日韩无码国产精品| 视频一区**字幕直播在线| 亚洲v天堂v手机在线观看| 国产精品亚洲一区二区在线观看| 免费看片网站有哪些| 中文字幕久久网| 国产精品美女| 最新中文字慕在线人妻| 亚洲一区二区激情视频| 日韩在线一区二区| 424亚洲福利视频一区二区| 欧美精品一区二区三区久久| 国产成人精品1024视频| 一级毛片特黄久久免费看| 国产福利在线观看免费第一福利| 欧美高清v| 久久精品免视看国产| 欧美人与牲动交a欧美精品| 国产美女免费网站| 亚洲欧美日本韩国| 免费看片的视频软件| 99久久精品免费看国产一区二区| 在线视频 亚洲 国产| 粉嫩小泬图片国产20p| 欧美成人看片黄a免费看| 亚洲综合综合在线| 亚洲国产欧美中文| 国产精品久久久久影院| 国产精品爱啪在线线免费观看| 手机在线国产精品视频| 亚洲大学生视频在线播放| 欧美亚洲情侣自拍视频一区 | 久久性综合| 国产三级精品三级在线专区港台| 妓女网一区二区三区| lutube免费看片| 无码专区第二页| 1024免费手机看片你懂的| 欧美激情综合一区二区三区| 国产97免费视频| 亚洲欧洲视频一区青苹果影院 | 066亚洲福利视频一区二区| 婷婷色香五月激情综合2020| 手机成人在线看片| 国产高清免费福利视频在线观看| 国产亚洲高清不卡在线观看| 窝窝影院午夜在线看片| 国产精品极品| 日本成人精品视频| 国产精品自拍一区| 亚洲欧洲视频一区二区| 国产精品久久久久国产这里有精品| 久久成人午夜| 免费日本看片| 中文字幕亚洲欧美精品视频| 99热成人精品国产免| 欧美丝袜一区| 在线观看国产精品99| 激情五月婷婷综合| 国产天天射| 亚洲视频在线观看一区二区| 久久一区精品| 精品国产网站| 在线看片三级| 国产精品观看视频| 国产a免费观看一级视频| 国产综合色在线视频区色吧图片 | 国产高清视频在线免费| 99精品欧美一区二区三区美图| 国产三圾片电影免费看| 成人无码网www在线观看| 日韩精品亚洲专区在线观看| 四虎影院久久久| 久久国产精品网| 欧美日韩国产免费一区二区| 亚洲一区二区三区在线观看蜜桃| 91资源在线视频| 成人看片软件免费| 亚洲欧洲视频一区青苹果影院| 中文字幕日本在线观看| 亚洲丝袜视频| 精品无码一区在线观看| 久久午夜免费视频| 手机看片免费版| 欧美日韩国产免费在线| 麻豆 国产 高清 无码| 成人国产在线观看高清不卡| 窝窝影院午夜在线看片| 秋霞电影网 在线看片| 国产三级精品三级在专区| 午夜无码伦费影视在线观看| 亚洲精品一二三四| 午夜免费成人| 亚洲国产美女视频免费| 久久这里只精品国产网址| 国产aa免费视频观看网站直播| 亚洲av小说| 中文字幕在线二区| 日韩一级片免费看| 欧美视频日韩视频| 猫咪视频在线看片| 国产精品全部久久| 国产成人精品免费网站| 免费国产在线视频| 亚洲男人的天堂无码一区二区| 亚洲欧洲久久久国产精品无码| 国产午夜精品久久理论片小说| 精品久久香蕉国产线看观看亚洲| 亚洲国产成人精品无码区| 国产凌凌漆免费观看国语高清完整版| 久久影院一区二区三区| 成年人视频在线观看国片99| 婷婷玖玖| 日韩欧美视频第一区在线观看| 国产欧美日韩在线不卡第一页| 国产精品九九久久| 国产三级精品三级在线专区港台| 久久这里只精品国产免费99热4| 国模国产经精品嫩模大尺度| 免费免国产在线播放| 成人精品视频一区二区三区| 91久久久国产亚洲精品蜜臀| 欧美色伊人| 日韩人妻无码精品综合网| 久久综合资源| 日韩欧美国产综合| 国产一区二区精品夜夜嗨| 亚洲国产精品无码久久98密柚| 亚洲欧美日韩综合一区久久| 91一区二区在线观看精品| 亚洲精品第二页| 亚洲人精品| 伊人久久婷婷| 性做久久久久久免费观看| 人妻一区二区三区无码精品一区| 亚洲欧美国产国产一区二区| 好吊妞欧美视频免费| 欧美精品一区二区三区视频| 国产女人综合久久精品视| 国产精品自产拍在线观看| 亚洲午夜一级| 色屁屁二区| 国产va在线| 久久国产综合尤物免费观看| 亚洲一区www| 97超碰国产精品无码| 国产一区欧美| 日本无遮挡吸乳叫声视频| 国产免费网站看v片元遮挡| 91国在线产| 一区二区三区日韩| 国产视频线上观看免费| 国产 精品久久| 国产精品娱乐| 国产精品自拍视频免费观看| 亚洲国产欧美在线人成swag| 91精品久久国产青草| 激情一区| 久久成人小视频| 中文字幕在线2021一区| 综合网婷婷| 人妻无码aⅴ不卡中文字幕| 在线人妻无码中文dvd视频| 国产V亚洲V天堂无码网站 | av在线看片| 亚洲欧美国产啊a在线| 国产成人91高清精品免费| 欧美久久久久久| 综合色亚洲| 精品久久久久久久九九九精品| 婷婷激情五月网| 亚洲欧美日韩国产精品网| 久草不卡视频| 国产伊人精品在线| 日本a圾片电影免费看| 在线看片www| 欧美天堂久久| 亚洲天堂久久精品成人| 国产爆乳乱码女大生Av| 国产大片免费完整版| 国产精品 日韩 在线| av在线一区二区三区| **在线看片你懂的| 亚洲欧美日韩综合在线| AV熟妇导航网| 亚洲精品无播放在线播放| 国产精品无码久久久久| 99久久国语露脸精品国产| 国产精品久久久久jk制服| 成人欧美日韩| 制服丝袜国产精品电影| 亚洲一区 视频在线| 国产福利亚洲视频91| 国产精品亚洲欧美日韩一区在线| 日韩五十路| 国产午夜免费拍视频观看视频男男| 国产亚洲精品俞拍视频| 综合在线亚洲| 加勒比无码免费专区中文| 国产精品久久亚洲不卡应用| 亚洲性线在线播放| 国产精品无码专区在线观看| 欧美激情亚洲一区中文字幕| 国产精品久久九九| 亚州综合网| 国亚洲欧美日韩精品| 久久精品国产香蕉**| 在线观看国产精品av| 久久99中文字幕| 久久亚洲国产精品影视| 在线看片免费**网不卡| 亚洲综合在线观看视频| 国产精品视频a区| 在线看片日本专区免费| 国产艳妇av在线出轨| 亚洲国产精品免费| 七月婷婷在线网址| 无码区a∨视频体验区30秒| 亚洲一区二区高清**| 久草视频一区| 久久国产成人亚洲精品影院| 久久国产精品99国产精| 亚洲国产日韩在线一区| 久久精品国产亚洲一区| 小火星在线看片| 欧美一区二区三区不卡| 久久精品**日韩av| 97久久久人妻一区精品| 少妇高潮后中文字幕| 手机免费看片软件| 视频一区亚洲色图| 99久久精品免费看国产情侣| 伊人成人久久| 亚洲成综合人影院| 久久国产精品免费专区| 国产亚洲人成a在线v网站| 国产成人av大片在线播放| 日本亚洲一区视频直播| 91精品国产高清久久久久久| 欧美亚洲日本精品| 日韩免费一区二区| 国产免费午夜a无码v视频| 国产**看片免费视频| 日本人妻一区二区三区不卡影院 | 久久亚洲视频一区| 成人另类视频| 精品视频国产香蕉尹人视频| 91久久香蕉国产线看观看软件| 久久久久久国产精品免费免费| 秋霞伦理手机在线看片| 婷婷六月激情综合一区| 国产丝袜大长腿精品丝袜美女图片| 久久精品国产精品亚洲蜜月| 在线观看亚洲精品福利片| 99久久国产免费-99久久国产免费 91精品国产福利在线观看 | 欧美区一区二| 宅男免费看片软件| 久久精品国产亚洲艾草| 伊人久久综合谁合综合久久| 97国产免费视频| 欧美日韩国产在线人成app| 超碰一区二区| 久久久青青| 国产精品**| 日韩欧美精品综合久久| 久久国产精品免费一区二区三区| 亚洲视频四区| 国产91视频免费观看| 手机看片免费视频| 久久综合国产亚洲精品首页| 日韩精品中文字幕视频一区| 99国产精品视频| 久草青青在线| 看片免费app| 国产精品女同一区二区久久| 这里只有精品99re在线| 精品国产免费观看久久久 | 亚洲另类自拍视频一区| 欧美日韩成人| 国产乱肥老妇精品视频| 欧美亚洲视频佛爷视频一区| 久久久久久久精品免费| 国产一区二区精品久久91| 亚洲国产精品一区二区首页| 亚洲精品国产综合99久久夜夜嗨| 免费看片软件app下载| 精品国产福利在线观看| 亚洲欧美日韩国产精品网| 免费观看国产视频| 日韩高清一区二区| 手机免费看片神器| 女子国产亚洲久久精品| 欧亚日韩精品一区二区在线| 国产精品视频video| 日韩精品久久久毛片一区二区| 528亚洲福利视频一区二区| 午夜精品一区在线观看| 91精品国产美女福到在线不卡| 久久国产精品免费一区二区三区| 中文字幕avv| 国产精品打着电话偷着情| 伊人网中文字幕| 国产a v无码专区亚洲av| 欧美亚洲视频一区无码最新章节| 日韩一区二区电影| 在线欧美一区| 国产亚洲中| 性欧美国产精品| 久久国产偷任你爽任你| 在线观看精品视频一区二区 | 亚洲一区二区另类视频| 国产精品亚洲А∨天堂免| 亚洲欧美高清| **看片 2019免费| 一区二区免费高清观看国产丝瓜| 亚洲一区www| 免费看片不收费的app| 久久亚洲精品影院| 久久国产乱子伦精品免费女人| 国产精品成人在线| 亚洲三级欧美| 亚洲无限乱码一二三四芒果| 国产91在线视频免费观看| 超碰Av一区=区三区| 国产精品久久久久a影院| 国产精品亚洲欧美一区在线| 久久精品国产在热亚洲电影大全| 亚洲jjzzjjzz在线观看| 国产精品一级毛片久久久| 亚洲精品**国产| 在线观看免费国产视频| 亚洲欧美日本国产综合在线| 国产亚洲欧美日韩在线观看一区二区| 国产亚洲欧美高清视频| 亚洲视频一区二区三区| 丝袜精品亚洲| 久久精品国产亚洲vr| 五月花社区婷婷综合| 伊人国产精品| 国产精品自拍一区| 免费三级看片| 制服空姐亚洲视频一区| 亚洲国产欧美日韩在线精品一区| 欧美激情亚洲一区中文字幕| 亚洲综合狠狠| 99热精品在线免费观| 亚洲欧美日韩国产自拍| 国产精品久久久久久久久岛| 国产69精品久久久久9999| 久久精品国产**香蕉| 亚洲AV高清在线观看一区二区三区| 亚洲精品在线免费观看| 欧美国产小视频| 亚洲国产手机在线观看视频| 韩国论理片免费看| 中文人妻AV高清一区二区| 国产精品久久久久国产精品| 国产高清一区免费视频| 久久综合九色综合97飘花| 国产成人久久精品二区三区| 永久黄网站色视频免费观看| 日韩亚洲欧美一区| 99riav视频国产在线看| 亚洲精品在线免费| 欧美日本一本线在线观看| 欧美亚洲另类在线| 在线看片免费不卡**| 国产一区二区精品视频| 国产亚洲精品无码不卡| 免费看污片软件| 亚洲国产综合精品中文第首页亚洲| 精品无码久久久久国产| 国产 精品久久| 国产精品影院| 国产在线精品美女观看| 亚洲精品国产在线观看| 国产h视频免费| 国产高清免费福利视频在线观看| 国产女主播免费一区| 亚洲国产精品久久九九九| 成人国产精品一区二区| 熟妇人妻不卡中文字幕| 国产1024在线观看免费视频| 久久精品国产**水果派| 国产手机视频免费观看一区| 国产精品美女在线免费观看| 亚洲国产综合精品中文第首页亚洲 | 亚洲一区二区视频大全| 亚洲视频在线观看一区二区三区| 国产精品自产拍视频| 国产精品自拍视频在线观看| 国产精品无码久久av| 1024手机看片永久免费| 国产免费网站看v片在线| 手机在线看片自拍| 精品一区精品二区| 亚洲国产精品看片在线观看| 国产高清国内精品福利99久久 | 免费现黄频在线观看国产| 国产福利电影免费看| 国产精品**三区明星艳照| 亚洲美女精品xx| 久久国产精品久久国产精品| 国产精品自拍电影在线观看| 八戒八戒看片在线观看免费动漫| 亚洲国产一区成人| 国产成人综合久久精品推荐免费 | 国产偷国产偷精品高清尤物| 亚洲国产成人精品女人久久久| 国产免费亚洲视频| 视频一区精品自拍亚洲| 91精品久久国产青草| 中文字幕日韩高清版毛片| 亚洲六月丁香色婷婷综合久久| 色噜噜一区二区三区| 91在线无码精品| 人妻无码αv中文字幕加勒比| 免费国产三级| 413亚洲福利视频一区二区| 视频一区二区**字幕最精准| 国产亚洲手机在线观看| 中文字幕三级久久久久久| 国产亚洲精久久久久久无码77777| 国产精品第二页| 久久国产精品**四虎| 久久国产精品免费专区| 在线看片免费观看不卡| 欧美一级片免费在线观看| 国产伦人伦偷精品视频| 亚洲在线 欧美精品| 亚洲高清视频免费的一区手机版| 久久午夜精品2区| 亚洲三级在线| 97青青青国产在线播放| 国产成人精品日本亚洲| **免费看片| 久久精品国产精品2020| 久久久久亚洲AV综合波多野结衣 | 国产精品国产三级国产an| 免费看片app成人| 中文字字幕国产精品| 精品久久伦理中文字幕| 国产一级在线视频免费播放| 国产精品亚洲影院| 99久久999久久久综合精品涩| 久久国产亚洲精品无码| 国产91福利在线精品蜜桃| 精品国产自在天天线2019| 精品一区二区91| 青青草这里只有精品| 免费国产**视频| 久久 精品 国产| 99久久99视频| 91在线真实产子伦| 亚洲高清不卡视频一区| 欧美成人一级视频| 日韩黄色在线视频| 久久成人国产精品一区二区| 色婷婷香蕉| 青青青国产在线免费观看| 在线观看国产欧美精品| 久久亚洲综合色| 久久精品国产72精品亚洲 | 亚洲日本网站| 亚洲免费国产午夜视频| 手机在线看福利片| 国产百合一区二区三区| 亚洲一区精品导航| 亚洲精品性夜夜夜| 99热成人精品国产免| 国产精品综合一区二区三区| 午夜成人免费视频| 亚洲精品国产精品乱码不卡√| 亚洲欧美精品日韩| 国产精品va在线播放| 欧美色精品天天在线观看视频| 亚洲国产精品综合久久网络| 看片在线看免费| 成人日韩在线观看| 国产成人无码精品久久久| 91精品国产品国语在线不卡| 久久精品国产亚洲尢物| 1看片免费播放器| 国产高清无遮挡高潮毛片| 国产自拍免费在线观看视频| 精品日韩欧美一区二区三区在线播放| 亚洲av免费在线| 092亚洲福利视频一区二区| 国产在线观看中文字幕| 亚洲一区二区精品视频在线观看 | 久久久久亚洲精品成人网小说 | 亚洲视频一区在线观看| 亚洲无码高清一区| 四虎国产精品永久在线播放| 亚洲国产手机免费在线观看| 国产精品**aa**在线看| 欧产日产国产精品99在线| 手机看片旧版免费| 在线中文字幕av| 国产精品视频video| 日本爽爽爽爽爽爽在线观看免| 国产精品k频道网址导航| 日本一区二区三区精品AⅤ| 91最新免费观看在线| 手机看片久久国产免费| 亚洲一区二区在线播放| 秋霞电影网院**片免费看| 激情亚洲婷婷| 在线看片不卡免费视频| 久久精品国产亚洲专区| 国产亚洲欧美日韩在线视频 | 国产在线视精品在亚洲 | 国产香蕉久久| 免费看片资源网| 日韩久久一区二区三区| 手机免费看福利片| 亚洲香蕉毛片久久网站| 国产亚洲欧美精彩视频| 久久精品国产**成人| 亚洲综合涩| 免费看国产**| 亚洲视频欧美视频| 欧美日韩亚洲一区视频在线观看免费| 久久免费视频一区二区| 国产亚洲欧美资源在线| 国产免费福利视频| 欧美精品导航| 在线观看国产人妻视频| 91精品国久久久久久无码蜜桃 | 亚洲精品国产电影| 日韩欧美网址| 久久精品久久精品| 国产男女猛烈无遮挡免费视频| 亚洲欧美国产日产综合不卡| 亚洲国产三级视频一区| 日韩视频福利| 免费在线观看亚洲| 国产精品久久久首页| 久久综合色视频| 99久久久无码国产精品| 无码一区二区三三| 在线看片z| 亚洲精品自拍图| 在线国产你懂的| 国产精品99久久久久久宅男| 国产一区在线免费观看| 伊人久热这里只有精品视频99| 欧美亚洲视频一区无码无广告弹窗 | 亚洲不卡的视频一区二区| 色综合综合| 欧美亚洲国产a视频| 精品**| 一本一本久久a久久综合精品蜜桃| 免费看一级片| 国产亚洲欧美精品综合在线| 亚洲国产精品久久| 色综合五月| 视频一区亚洲综合app免费下载| 国产99久久九九精品无码区| 日韩欧美一区二区三区视频| 亚洲欧美视频一区最新章节 | 亚洲天堂首页| 久久网国产| 手机看片1024免费新版| 亚洲精品色网| 久精品国产欧美亚洲色aⅴ大片| 成人午夜网址| 国产成人精品怡红院在线观看| 日韩高清专区| 国产精品欧美激情第一页| 国产原创久久精品| 亚洲精品免费福利视频| 国产人成无码视频在线app软件| 亚洲综合在线一区视频在线观看| 亚洲日韩中文字幕在线播放| 久久成人国产精品| 国产亚洲精品免费| 秋霞午夜国产精品成人片| 国产精品日韩| 1024手机在线免费看片你懂的| 国产欧美在线观看精品| 国内喷白桨黄色网站| 激情久久免费视频| 国产日韩第一页| 亚洲喂视频一区| 国产国产成年年人免费看片| 黄色高清无码免费看| 亚洲国产欧美在线| 久久午夜夜伦伦鲁鲁片| 亚洲**视频一区| 国产精品日韩精品在线| 亚洲精品国产成人久久| 99久久婷婷国产综合精品电影| 欧美精品99| 97av在线网站| 国产精品国三级**| 亚洲专区日韩精品| 日韩丶欧美丶国产高清不卡视频| 提供最新的在線欧美综合一区| 日韩亚洲精品不卡在线| 亚洲欧美国产动漫| 手机免费看片日韩| 亚洲一区二区激情视频| 国产69精品久久久久9999不卡| 国产资源免费| 国产本道久久一区二区三区| 无码高潮喷吹在线播放亚洲| 精品在线观看一区| 国产一区二区三区在线看片| 伊人成综合网| **在线看片| 国产3p精品视频免费版| **在线不卡精品国产| 亚洲精品国产在线视频| 亚洲人成精品影院在线播放影院| 性做久久久久久免费观看| 一本一本久久a久久综合精品蜜桃| 亚洲国产精品自产拍在线播放| 欧美日韩一区二区综合| 中文字幕亚洲欧美日韩不卡 | 精品国产美女福利到在线不卡| 看片免费视频软件| 国产精品久久网| 久久国产精品一国产精品| 精品**免费| 国产精品自拍视频在线观看| 日本韩国亚洲精品| 久久久久有精品国产麻豆| 国产h免费视频| 久久丫精品国产**网站| 国产精品久久久久久亚洲按摩| 亚洲无码免费| 国产精品久久久亚洲**| 久久精品国产亚洲无删除| 亚洲AV无码一区二区二三四区| 日本国产亚洲| 1769国产在线观看免费视频| 国产精品免费视频观看视频| 国产亚洲精品免费观看| 亚洲欧美日韩精品专区| 国产日韩精品欧美一区喷水| 国产精品无码久久av| 亚洲一区视频手机在线| 国产主播精品系列| 免费看的黄色一级片| 网站在线看片| 国产成人久久精品二区三区牛| 在线视频中文字幕| 欧美精品导航| 国产成人1024精品免费| 日韩毛片无码| **亚洲一区| 加勒比一区| 国产精品成人99久久久久| 日韩免费无码一区二区视频| 怡红院一区二区三区| 久久精品国产亚洲黑森林| xxx国产精品xxx| 亚洲av永久无码精品成人| 国产AV网站18禁止人| 精品国产自在天天线2019| 日韩免费视频一区二区| 国产v片在线观看免费播放| 欧美亚洲国产a视频| 91综合网| 色欲麻豆国产福利精品| 香蕉久久人人爽人人爽人人片AV| 久久九九免费精品国产| 精品少妇人妻av一区二区| 国产亚洲精品美女久久久久久久久| 久久精品国产精品免费专区| 欧美亚洲国产一区二区| 久久国产精品**四虎| 在线亚洲欧美综合视频一区手机版| 久久国产热精品波多野结衣av| 精品**免费| 一区精品在线| 久久精品国产亚洲桃乃木香奈| 亚洲mv国产mv在线观看| 国产成人精品免费久久久久| 有没有可以免费看片的软件| 国产在线播放一区二区| 在线观看国产精品av| 伊人国产在线观看| 国产精品美女免费视频| 亚洲日韩一区二区三区不卡 | 日本不卡视频网站| 国产精品观看视频| 亚洲嫩草精品| 亚洲国产精品福利视频| 五月天高清无码| 亚洲国产在线观看在| 五月天国产在线视频| 手机看片在线免费播放| 国产美女亚洲精品久久久大胆写真图片高清 | 精品国产网红福利在线观看| 国产精品亚洲一区二区视频| 最新在线你懂的| 97av在线网站| 美女内射在线免费观看| 亚洲欧美国产日韩视频在线观看| 中文字幕成人| 欧美日韩国产在线观看免费| 国产拍揄自揄精品视频| 亚洲人成在线播放| 1024手机看片免费观看| 麻豆精品新a v视频中文字幕| 97在线看片| 亚洲国产精品久久电影欧美| 欧美亚洲网| 国产欧美日韩亚州精品专区| 久久99国产乱子伦精品免| 视频一区亚洲视频无码| 国产人成无码视频在线app软件| 影音先锋在线看片网站| 国产免费福利小视频在线观看| 欧美日本一区| 国产亚洲欧美专区精品| 欧美成人性色区| 日韩中文精品亚洲第三区| 国产视频a精品| 亚洲精品456在线观看| 番茄todo社区看片在线观看免费版下载| 免费一级国产大片| 最新中文字幕在线播放| 亚洲欧洲视频一区_**男人的天堂| 国产成人精品免费视频版大全软件| 欧美一级片在线免费看| 亚洲精品高清国产不卡在线| 欧美色爱综合| 日本在线看片免费**1000| 亚洲国产综合精品中文第首页亚洲| 99在线视频网站| 亚洲国产精品久久人人爱| 国产精品久久亚洲不卡999| 国产一区二区三区在线观看免费| 亚洲视频免费一区百度图片搜索| 99精品一区二区三区无码吞精| 伊人99在线| 视频一区精品自拍亚洲| 精品国产呦系列在线观看免费| 久久国产午夜一区二区福利| 日本看片网站免费| **精品| 亚洲AV乱码一区二区三区按摩| 亚洲综合色一区二区三区| **在线不卡精品国产| 亚洲狼人在线| 久久6这里只有精品| 手机看片久免费国产| 亚洲国产精品成人综合色| 亚洲国产激情| 亚洲无码偷拍视频| zt5app免费看片| 国产欧美亚洲精品在线| 亚洲一二三在线| 亚洲伦理中文字幕一区| 成年人片免费看| 992人人tv香蕉国产精品| 亚洲免费高清| 国产精品一区二区不卡的视频| 亚洲国产爱在线视频| 日本**亚洲视频一区| 国产精品久久亚洲不卡动漫| 欧美国产日产一区二区| 中文字幕在线一区二区| 亚洲视频免费一区变态视频| 国产99久久久国产精品免费观看| 亚洲欧美啪啪视屏| 久久精品国产亚洲综合色 | 在线看片免费观看不卡| 麻豆视频亚洲一区在线观看| 亚洲国产精品久久九九九| AV网站官方在线| 国产一区二区精品久久91| c片免费看| 亚洲欧洲视频一区免费在线阅读| 国产精品高清av一区二区三区| 成人毛片18女人毛片免费| 亚洲精品98久久久久久中文字幕| 狠狠干精品| 日韩手机看片免费| 416亚洲福利视频一区二区| 精品国产一区二区三区久久影院| 国产成人一区免费观看| 夜夜爽无码一区二区三区| 一区二区自拍| 视频二区好吊色永久视频| 光棍天堂在线看片| 看片软件下载app大全免费| 视频一区欧美视频 亚洲| 国产在线成免费观看视频| 欧美在线观看www| 夜夜爽无码一区二区三区| 欧美区国产区| 在线观看亚洲一区| 欧美综合视频在线观看| 午夜免费福利在线观看| 手机在线看片导航| 不卡免费看片| 国产精品亚洲专区无码不卡| 视频一区亚洲视频无码小学| 视频亚洲精品一区在线播放| 精品国产日韩亚洲一区| 亚洲精品有码在线观看| vvvv99亚洲精品欧美| 国产一区二区三区在线观看免费 | 久久精品亚洲福利视频一区二区三区| 国产三级精品三级在专区| 国产小视频在线播放免费| 久久国产亚洲精品在线免费观看 | 久久97精品久久久久久久看片| 欧美激情人成日本在线视频| 欧美一区二区在线| 日韩精品福利在线| 欧美一级日韩一级亚洲一级va| 一个人看的www片免费高清中文| 成人看片在线观看免费高清| 手机看片免费福利永久| 亚洲一区二区国产精品无码| 看片的免费网址| 92手机免费看片| 亚洲v片免费看| **免费看| 国产亚洲欧美精品综合在线| 国产成人咱精品视频免费网站| 在线看片胔| 日本九九精品一区二区| 91福利在线视频| 欧美专区在线视频| 精品伊人久久大香线蕉网站| 国产成人在线小视频| 91国内外精品自在线播放| 色婷婷综合在线| 婷婷激情在线| 亚洲狠狠婷婷综合久久久久网站| 国产毛片在线看| 无遮无挡爽爽免费毛片| 麻豆99久久免费国产精品| 久久精品高清一区二区三区| 精品国产一区二区三区不卡在线| 亚洲国产精品合集久久久久| jk福利影视在线| 亚洲国产精品久久久天堂不卡 | 在线看片的播放器| 国产小视频在线亚洲| 久久青青草原精品国产不卡| 精品国产三级v| 99久久99热精品免费观看国产| 久草视频福利资源站| 亚洲系列一区中文字幕| 国产亚洲久久久精品影院| 久久亚洲精品无码| 精品无码久久久久久国产| **第一页国产精品| 国产成人av在线| 日批视频网址免费观看| 色婷婷综合中文久久一本| 久久无码精品一一区二区三区| 久久夜色精品国产亚洲噜噜| 国产欧美精品亚洲| 欧美日韩亚洲视频一区大全| 亚洲欧洲日本国产| 久久亚洲精品无码| 国产午夜亚洲精品不卡| 亚洲精品无码久久久| 亚洲国产精品电影人久久4| 国产午夜人做人免费视频| 亚洲日韩欧美视频一区| 免费在线看片的网站| 国产成人福利在线| 国产无码第十页| 久久精品国产在热亚洲香蕉太| 国产欧美日本亚洲精品| 亚洲中文AⅤ中文字幕在线| 亚洲色国产欧美日韩| 日本一区二区免费在线观看| 网友自拍第一页| 久久这里只精品国产免费| 亚洲欧洲视频一区二区| 日本一区不卡视频| 亚洲视频国产精品| 亚洲日韩精品无码| 狠狠亚洲视频一区| 成年女人看片免费视频| 亚洲人成网男女大片在线播放| 中文字幕日韩精品亚洲七区| 国产成人精品一区二区不卡| 国产精品夜间视频香蕉| 亚洲国产综合在线观看不卡| 四虎亚洲国产成人久久精品| 91在线真实产子伦| 视频一区亚洲资源| 欧美国产综合视频| 国产xx在线观看| **午夜精品| 免费看片影院| 国内精品视频一区二区三区八戒| jk福利影视在线| 亚洲欧美迅雷视频一区| 色综合久久久久久久久五月| 妓女影院一区二区在线观看| 国产精选免费观看| 手机永久免费看片| 国产精品成人亚洲| 国产亚洲欧美精品综合久久799 | 久久视频依人网亚洲一区| 国产欧美精品午夜在线播放| 国产91精品对白露脸全集观看| 久久****精品二区| 在线看片日本专区免费| 99re视频这里只有精品| 久久精品国产**麻豆车振| 久久国产有精品| 亚洲国产精品福利片在线观看| 青青青国产免A在线观看| 视频一区亚洲视39| 韩国视频一区二区| 日韩无码视频一区| 现在哪里有免费的那种片子看 | **一级片免费看| 国产高清一区二区三区四区| 中文字幕精品亚洲字幕资源| 日本欧美一区二区三区| 亚洲中文久久精品无码ww16| 国产亚洲欧美精品视频| 亚洲av无码专区国产乱码电影| 日本中文字幕网址| 久久亚洲春色中文字幕久久久| 伊人精品视频在线| 国产亚洲精品无码不卡| 午夜精品福利在线观看| 国产精品网曝门免费视频| 亚洲愉拍自拍视频一区网手机版| 久久久久夜色精品波多野结衣| 国产午夜免费视频| 欧美成人看片黄a免费看| 全部无卡免费的毛片在线看| 99精品国产一区二区三区| 国产成人亚洲综合网站不卡| 亚洲精品高清国产一线久久| 1024手机在线看片基地| 国产色噜噜| 亚洲新视频一区二区三区四区五区 | 亚洲欧美视频一区在线| 亚洲一区欧美日韩| 亚洲欧美日韩精品视频在线观看| 国产在线观看91精品一区| 国产69囗曝护士吞精在线视频| 日本免费看片视频| 91精品啪在线观看国产| **精品影院| 国产综合精品在线| 国产精品美女久久久久av福利 | 国产精品爽爽va在线观看无码| 在线播放精品一区二区啪视频| 久久国产精品99国产精| 伊人久久婷婷| 久久国产欧美日韩精品| 97精品视频在线| 精品国产自在现偷| 欧美日韩资源| 四虎国产精品永久入口| 欧美成人二区| 亚洲综合视频一区二区| 日韩黄色大片免费看| 精品亚洲视频一区二区三区| 亚洲AV高清在线观看一区二区三区| 伊人久久大香线蕉无码麻豆| 国产精品第八页| 亚洲国产精品福利视频| 麻豆99久久免费国产精品| 欧美黄色一级片免费看| 五月天国产在线视频| 在线看片免费不卡| 精品久久香蕉国产线看观看亚洲| 国产精品午夜久久| 久久99国产精品久久| 一本久道久久综合| **精品一区| 日韩一区二区三区免费视| 看片免费的app| 精品国产免费一区二区| 久久精品国产国产精品四凭| 成人国产精品一区二区免费看| 国产精品亚洲欧美日韩一区在线| 精品香蕉国产线看观看| 久久综合综合久久| 番茄todo社区免费看片| 久久精品国产96精品亚洲| 91久久国产精品视频| 在线精品国产电影| 8AV国产精品爽爽ⅤA在线观看| 91短视看片在线观看免费| 国产精选在线播放| 麻豆精品视频网站在线观看| 国产精品电影在线看| 国产一区二区精品久久91| 亚洲视频视频一区在线| 国产成人亚洲精品无码电影| 欧美亚洲日本国产其他| 国产精品日韩欧美| 伊人国产精品| 亚洲色拍偷拍一区视频大全| 久久综合第一页无码| 亚洲人成伊人成综合网久久久| 久久这里有精品国产| 欧美天天在线| 国产亚洲欧美精品在线播放| 国产精品日韩电影| 激情综合婷婷| 国产欧美亚洲首页| 久久精品国产99国产精品免费看| 国产伦一区二区三区免费| 四虎影视国产精品亚洲精品| 亚洲精品国产精品| 国产乱人伦真实精品视频| 久久精品无码一区二区三区| 国产亚洲欧美专区精品| 国产aⅴ激情无码久久久无码| 中文字幕一区二区在线观看| 国产精品国产三级国快看| 色偷偷一区| 久久6这里只有精品| 亚洲自拍视频一区| 久久精品国产**无| 另类激情亚洲| 麻豆一级片| 亚洲欧洲视频一区老鸦窝| 久久久久亚洲AV无码专| 亚洲午夜免费视频| 亚洲国产日韩在线欧美综合| 国产娱乐精品| 色综合久久夜色精品国产| 国产精品久久久久久久久久98 | 亚洲成a人片在线观看中文| 亚洲综合成人网在线观看| 成年女人看片永久免费视频| 手机国产乱子伦精品视频| 波多野结衣色av一本一道| 99久久综合狠狠综合久久| 369看片手机看片免费看片| 国产精品久久久久久久久| 亚洲第一黄片大全| 亚洲午夜在线观看| 影音先锋在线看片资源网| 亚洲日美韩视频一区在线观看| 亚洲国产精品久久久天堂| 国产91在线播放| ******综合| 国产精品亚洲欧美高清| 国产日产精品久久久久久婷婷| 99re免费在线视频| 久久综合九色综合精品| 亚洲三级在线免费观看| 久久这里只精品国产777| 国产手机精品在线播放| 亚洲狼人在线| 99久久免费午夜国产精品| 国产亚洲精品无码不卡| 片在线观看免费看| 99久久精品免费看国产一区二区| 亚洲**国产精品久久| 精品无码国产一区二区三区麻豆| 奇米影视一区二区三区| 国产亚洲亚洲精彩视频| 伊人久久大香线蕉无码麻豆| 久久国产精品真实| 欧美久久精品另类国产亚洲| 天堂在线亚洲| 久久精品国产免费中文| 久久综合久久a| 在线看片胔| 手机看片免费网址| 亚洲v视频日韩一区二区| 精品国产99在线观看| 免费国产亚洲视频在线播放| 亚洲综合一二三区| 自拍偷自拍亚洲精品10p| 精品国产美女福利到在线不卡| av片在线看| 夫妻免费看片| 国产人做人爱视频精品| 国产精品真实交换视频| **国片免费| 国产**免费观看| 亚洲国产精品久久久久婷蜜芽 | 亚洲av中文无码乱人伦在线r| 午夜手机在线看片| 手机看片夫妻免费| 午夜不卡AV免费| 亚洲一区视频现看小说| 精品 日韩 国产 欧美在线观看| 日韩亚洲国产高清免费视频| 亚洲**国产精品久久| 99久久久无码国产精品4老年人| 《五十路》久久| 久一在线视频| 亚洲明星中文字幕AⅤ无码| 日本久久中文字幕| 久久久久久久九九九九| 国产欧美日韩在线观看一区二区三区| 日韩精品中文字幕在线| 国产3344永久在线观看视频| 日韩中文在线视频| 国内久久精品视频| 日韩欧美一区二区在线观看| 国产亚洲日韩在线播放不卡| 欧美亚洲国产日韩在线视频| 国产亚洲福利视频| 亚洲福利一区二区精品秒拍| 在线观看亚洲国产视频| 亚洲国产手机免费在线观看| 亚洲国产人成在线视频| 久久青青成人亚洲精品| 国产爽的冒白浆的视频高清| 亚洲mv日韩mv国产mv| 亚洲欧美日韩国产综合v在线观看| 手机在线看片影院| 91成人国产网站在线观看| 精品成人乱色一区二区| 精品国产亚洲一区二区三区在线观看 | 日韩激情中文字幕| 久久精品黄片| 久久亚洲国产精品亚洲老地址孕妇| 国产亚洲精品美女久久j久久| 亚洲国产精品无码中文字满| 久久精品国产**麻豆导航| 心灵法医国产剧全集免费观看 | 国产欧美亚洲精品第一页久久肉| 中国a级毛片免费观看| 免费无码国产v片在线观看| 啦啦啦免费黄色视频| 久久公开视频| 伊人久久大香线蕉av影院| 国产视频一二| 国产精品亚洲影院| 国产精品夜间视频香蕉| 中文字幕制服诱惑国产精品| 国产精品娱乐| 国产欧美日本亚洲精品| 亚洲综合色一区二区三区另类| 在线欧美国产| 亚洲中文字幕久久精品蜜桃| 大伊香蕉精品视频一区| 久久99久久99精品免观看| 精品**免费| 国产尤物精品视频| 国产精品自拍| 国产亚洲欧美在线综合| 国产丝袜一区二区在线播放| 精品成人毛片一区二区视| 色欲国产一区二区亚洲高清| 色欲AV无码一区二区人妻| 日韩aⅴ在线观看| 国产日韩精品视频| 亚洲欧美另类视频一区| 亚洲国产日韩在线人高清vr| 免费中文字幕不卡视频| 中国国产一级毛片视频| 一级片麻豆| 亚洲国产精品国自产拍av| 亚洲欧美日韩自拍视频一区| 理论片在线看片三免费| 精品免费久久| 欧美在线Aⅴ性色| 香蕉久久一区二区不卡无毒影院| 亚洲精品自拍图| 亚洲欧美日韩视频一区| 在线看片日韩| 99re国产视频| 亚洲黄色网站在线观看| 久久久精品国产**日韩| 手机看片日韩免费高清| 久久国产精品亚洲一区二区| 亚洲国产免费| 影音先锋国产在线| 国产精品无码| 1024手机在线看片欧美| 日韩午夜高清福利片在线观看| 欧美日韩国产一区二区三区| 91麻豆亚洲国产成人久久精品| 日韩欧美国产精品亚洲二区| 在线看片 a| 日本a在线播放| 91在线无码精品秘九色APP| 亚洲精品国产成人在线| 免费看片播放| 自拍亚洲国产| 亚洲AV永久无码精品一区二国| 中文精品久久久久国产| 黄色a级片免费看| 国产精品免费久久| 亚洲国产另类久久久精品女同| 210亚洲福利视频一区二区| 日本一区二区三区在线观看| 国产色婷婷精品免费视频| 久久精品亚洲国产欧美91| 亚洲色综合视频一区全集在线观看 | 国产精品亚洲专区无码不卡| 在线看片 a| 一本大道香蕉最新在线视频| 国产片免费在线观看| 亚洲欧美日韩国语视频一区| 天天夜天干天天爽| 久久99精品久久水蜜桃| 394亚洲福利视频一区二区| 亚洲三级网| 国产精品久久久久久影院| 国产精品**视频一区二区三区| 在线看片55k| 久久99精品福利久久久| 亚洲精品国产亚洲第一| 67194在线看片| 国产95在线 | 亚洲| 国产欧美精品亚洲| 国产亚洲欧美资源在线| 国产99re在线观看只有精品| 制服丝袜三级国产精品| 欧美一区二区在线观看| 亚洲国产高清精品线久久| 国产欧美亚洲精品第一页亚洲欧美| 国产在线精品亚洲第一区香蕉| 国产精品毛片一区二区三区| 国产精品视频一区无码| 午夜剧场成年片在线看| 欧美亚洲国产第一页草草| 国内精品国产三级**| 久久夜色精品国产尤物| 丁香婷婷色| 最新亚洲av日韩av一区二区三区| 亚洲第一无码| 亚洲国产精品久久久秋霞免| 岛国片在线免费看| 久久久久无码国产| 亚洲欧美国产中文视频一区| 亚洲国产欧美日韩精品一区二区三区 | 欧美亚洲国产一区在线观看 | 国产婷婷色| 手机看片国产免费| **片免费看| 91在线在线啪永久地址| 国产精品无码2021在线观看| 久久精品色| 国产亚洲精品免费视频| 亚洲视频综合| 久久精品国产亚洲aa| 手机免费看片福利盒子| 高清免费毛片| 久久精品国产欧美日韩| 一本加勒比HEZYO无码人妻| 232亚洲福利视频一区二区| 亚洲天堂欧美| 国产欧美亚洲精品a| 热99精品| 免费片国产| 九九视频这里只有精品99| 国产一级艳片免费手机观看| 久久久久一区二区三区| 97超碰精品成人国产| 丝瓜视频ios在线看片| 在线视频一区色| 制服丝袜片在线看| 久久精品re| 国产亚洲精品a**在线播放| 色综合欧美综合天天综合| 亚洲国产精品欧美| 99热免费在线观看| 夜夜看片免费区| 国产色噜噜| 韩国免费看片| 五十路中文字幕| 亚洲精品国产欧美日韩在线| 久草不卡视频| 色婷婷婷婷| 亚洲福利国产精品合集在线看| 91午夜在线| 色偷一区国产精品| 亚洲精品国产日韩| 331亚洲福利视频一区二区| 亚洲精品福利在线观看| 国模国产经精品嫩模大尺度| 日本少妇一级做α| 黄在线看片免费**| 久久亚洲精品国产亚洲老地址| 九九热精品视频在线观看| 国产一区在线观看免费播放| 欧美精品第一区| 国产精品美女在线播放| 国产色噜噜| 国产va免费不卡看片| 亚洲午夜久久久久中文字幕久| 国产亚洲视频在线观看网址| 欧美日韩国产免费| 99精品视频在线播放2| 亚洲欧美在线不卡视频一区| 免费伊人网| 欧美亚洲国产动漫| 国产线播放免费**| 欧美视频区| 夜夜爽夜夜叫夜夜高潮漏水 | 日韩黄色在线视频| 成人毛片在线播放| 国产呦精品系列| 日本www.在线中文字幕| 夜色在线影院在线看片| 国产免费高清视频一区| 国内欧美一区二区三区| 国产精品一区| 国产一区二区三区久久| 日本欧美亚洲| 国产精品一区影院| 97se综合自在线| 99爱精品| 久久精品国产免费播| 网友自拍第一页| 国产成人精品日本亚洲| 国产娱乐精品| 免费伊人网| 国产区在线观看| 678亚洲福利视频一区二区| 亚洲精品嫩草研究院久| 少妇性饥渴无码A区免费| 国产精品一区影院| 免费视频久久久| 欧美亚洲国产精品一区| 亚洲国产另类精品| 国99精品无码一区二区三区 | 视频一区二区三区在线| 亚洲欧洲视频一区3166全集| 精品一区二区久久久久久久网精| 91亚洲免费| 手机免费看片神器| 日本亚洲精品日本无吗专区| 午夜av无码福利免费看网站| 国产亚洲小视频在线| 国产高清精品久久| 天堂网av最新在线| 99久久国产亚洲综合精品| 免费看片不用下载播放器|Contact us

Tel:+86-0737-6685966

Email:export@skylinesmt.com

Address:Building H1, Standardized Factory, East New District, Hi-tech Zone, Yiyang City, Hunan Province

LINKEDIN:https://www.linkedin.com/in/zeng-hugo-611046195/ FACEBOOK:https://www.facebook.com/skyline.tech.88888 whatsapp/skype/wechat: +86 18163616773Online message

Copyright © 2019 Hunan Skyline Smart Material&Technology Co., Ltd. Recordcode:湘ICP備19004376號(hào)-1 Business license enquiry Map Technical support:jingwangzhiying

- Solution